EN NY SKYTEOPPLEVELSE

Kongsberg Target Systems er blant verdens ledende leverandører av elektroniske skyteskiver.

Vi har alltid hatt et mål om å levere fleksible og gode løsninger til skytterlagene, samtidig som vi leverer brukervennlige løsninger til alle skytterne. Nå gjør vi det igjen!

Velkommen til framtiden, når vi nå introduserer Kongsberg eScore.

MØT OSS HER:

KONGSBERG ESCORE

Det har blitt testet og verifisert på noen av verdens største skytebaner. Det har kostet over 40 millioner kroner å utvikle. Nå er det endelig her. Kongsberg eScore, verdens første hel-digitale og skybaserte løsning for framtidens skytebaner. Utviklet av skyttere, for skyttere.

FORDELER:

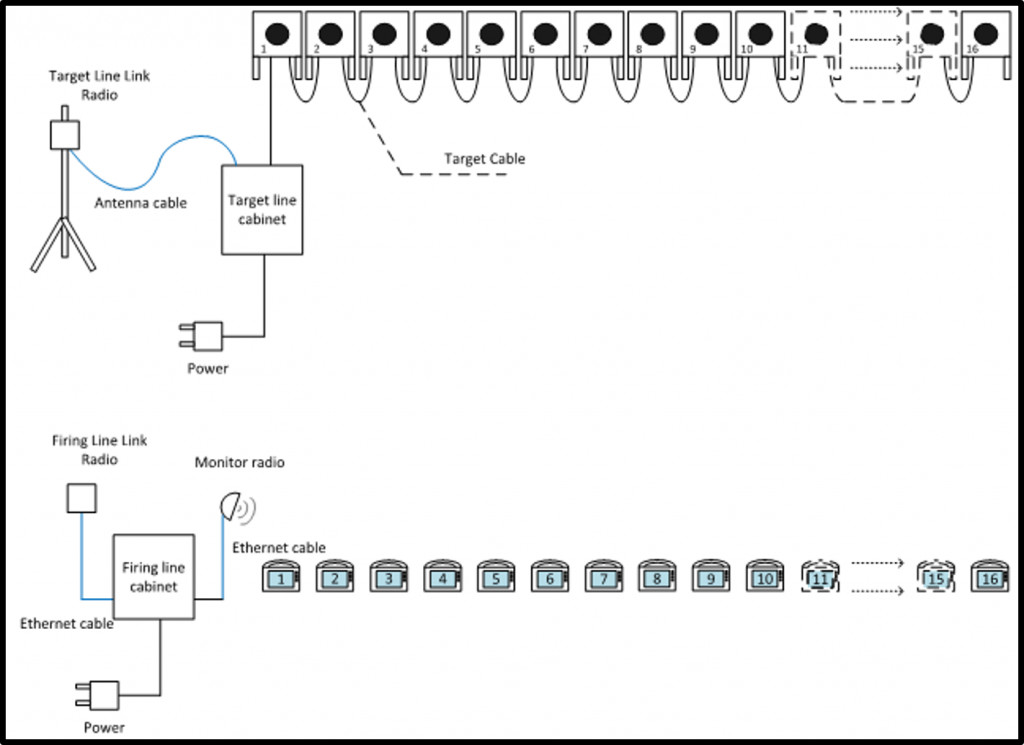

ENKLERE BANEDESIGN

Kongsberg eScore gir full fleksibilitet når det gjelder banedesign og ombygging av skytteranlegg. Vår unike design med trådløs teknologi og batteriløsninger sikrer at skiver og standplasser kan plasseres akkurat der du ønsker. Vi har lang erfaring med design av skytteranlegg, og gir gjerne råd om hvordan du kan bruke den nye teknologien til å optimalisere ditt eget anlegg

ENKLERE INSTALLASJON

Installasjon og oppsett av skytteranlegg har aldri vært enklere.

MED KONGSBERG ESCORE:

- Ekstremt enkel installasjon (plug-and-play).

- All programvare er ferdig installert når anlegget leveres for å forenkle oppkoblingen.

- Trådløs teknologi sørger for rask og enkel oppkobling av gravene mot standplass og monitorer.

Kongsberg eScore bidrar til effektiv og enkel installasjon, og det er ekstremt enkelt å komme i gang med skytingen på et nytt anlegg.

BRUKERVENNLIG

Full oversikt.

MED KONGSBERG ESCORE:

- Anvisning på robuste, trådløse monitorer med moderne berøringsskjermer.

- Dynamiske drop-down menyer som gir enkel tilgang til all relevant informasjon.

- Skivene justerer seg automatisk til riktig kaliber og skyteavstand. Ingen innstillinger, det er bare å skyte.

ENKLERE SERVICE OG VEDLIKEHOLD

En ny verden av muligheter som gir enklere og mer effektivt vedlikehold.

MED KONGSBERG ESCORE:

- Blinkdefinisjoner og skyteprogrammer lastes ned automatisk.

- Skyteresultater kan vises i sanntid via internett.

- Kongsberg eScore skiver har sensorer og elektronikk som gir full oversikt over status pr skive. Disse dataene er tilgjengelig for skytterlaget og bidrar til en helt ny hverdag for driftsansvarlige.

- All programvare oppdateres automatisk. Dette er også med på å forenkle jobben til driftsansvarlig.

NY STEVNESTYRING

Nye og visuelle løsninger som tar stevnestyring til et nytt nivå.

KONGSBERG ESCORE STEVNESTYRING:

- Ingen installasjon på PC. Alt kan kjøres via en nettleser fra et vanlig nettbrett eller PC.

- Moderne og brukervennlig.

- Ekstremt robust, med kontinuerlig og automatisk lagring og sikring av skudd-data.

- Unikt grafisk grensesnitt med oversiktlig visning av status for hver skytter og samlet lag.

- TCP/IP-kobling mellom resultatservice og stevnestyring. Dette gir en dramatisk forenkling når det gjelder overføring av data.

Personlig skytedagbok

Lag din egen, digitale og personlige skytedagbok. Dagboken gjør det enkelt å lagre alle skudd med tanke på framtidig analyse og læring.

SKYTEDAGBOK FUNKSJONER:

- Enkel og rask innlogging med QR code.

- Automatisk lagring av skudd på trening eller konkurranse. Enkelt å legge til personlige kommentarer.

- Enkel tilgang til lagrede skudd for referanse og analyse.

EN UNIK LØSNING FOR FRAMTIDEN

En ny generasjon av elektroniske skyteskiver.

Kongsberg eScore er den første løsningen av sitt slag i verden, med en unik kombinasjon av moderne elektronikk kombinert med moderne datateknologi og skytjenester. I månedene og årene som kommer vil vi fortsette å legge til nye løsninger som bidrar til enklere drift av anleggene, bedre stevner og gode skyteopplevelser.

Abonnér gjerne på vårt nyhetsbrev hvis du ønsker å få informasjon når vi lanserer nyheter.